Food, Feed, Cosmetic

Enzymes and Apple Juice processing

Fruit juice production is an essential segment of the Beverage industry throughout the world and apple Juice is the most popular juice over all.

To the average person, fruit juice production is a simple concept, just squeeze and collect the juice. As with most things, the process is much more complex, especially when processing several tons at a time. Other issues such as increasing yield, controlling clarity, sweetness and shelf life are all important factors for juice processors. Therefore, manufacturing fruit juice in a cost-effective manner requires significant technical expertise at every step in the process.

There are many variables to consider. These range from choosing the right kind of press to how early harvest apples differs from late ha'rvest or stored apples. Other issues include how to maintain a consistent level of sweetness and larifying the final product.

Nutrition Facts:

• One medium apple produces 3/4 cup or 6 oz of apple juice.

• One medium apple produces 1/2 cup of applesauce.

• 1-3/4 apple produces one serving of apple juice (8 oz. or 240 ml) = 120 calories.

• The average person worldwide eats 50.8 pounds of apple products a year. About 37% is consumed as fresh apples and 63% is in processed products (juice, sauce, etc.).

• 51 % of processed apples go for juice and cider.

Other uses include dried fruit, frozen; fresh apple slices, canned applesauce and vinegar.

Harvest

The time of harvest depends on what part of the world you reside. In the U.S., apples are harvested in the Fall. Apples must be tested for "maturity" to determine if they're ready to be picked. Apples that are harvested too early may taste sour or starchy, and apples harvested too late may be soft and mealy. The criteria for determining maturity include (1) sugar content (2) firmness (3) seed (4) skin color. Apples are still predominantly picked by hand, though some growers now use some mechanical methods.

Processing Apple Juice

Typical Processing Procedures for Apples:

1) Visual inspection: looking for mold, spray residue, etc. (ut or misshapen apples are okay for juice.

2) Washing: Apples are then water-washed by various methods for 10 to 45 minutes. Processors sometimes add chlorine dioxide, hypochlorite or other chlorine compounds to control microbial buildup in re-circulated water. Some washing includes physical scrubbers, which can actually reduce wash time. The extensive washing procedures effectively remove external surface dirt and topical agrochemical residues (pesticides).

3) The Mash: From the washers, the apples are chopped up by a grinder, apple mill or a "hammer mill" and turned into apple mash. To produce a highly pressable mash, it should not be ground too fine, stirred or heated above 35°( (95°F). When treated with pectinases, the temperatures range is kept mild, from 20-30°C and the reaction time is typically 30 to 120 minutes. This is in part to limit the hydrolysis of protopectin. Protopectin binds the cells and its hydrolysis weakens the fruit tissue, reduces its pressability and increases viscosity.

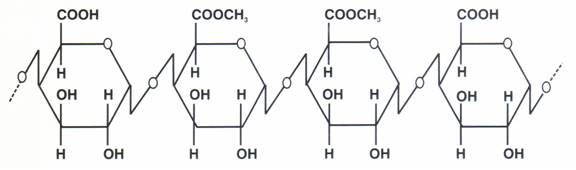

Apples, like other fruit are high in pectin, especially in the core. Pectin is generally a straight chain polymer of D-Galacturonic acid with alpha1,4-glycosidic linkage interspersed with some L-Rhamnose. It's found in cell walls of plants along with hemicellulose.

The addition of Pectinase to the mill is very beneficial, especially for apples with a soft texture. Pectinases developed for apple mashescontain a high percentage of pectin esterase and polygalacturonase (aka pectin glycosidase).

These enzymes dramatically reduce viscosity and the stickiness of the pomace, without affecting protopectin or reducing its pressability. Enzyme blends that include cellulase and hemicellulase activity can break down the cell wall and increase

the over-all juice production by 5-10%. However, there can also be an increase in cellobiose (finessmall molecules). When blend of this type are used, the minimum amount should be used and for the shortest period of time. This will greatly reduce the production of cellobiose.

• LiquiSEB-RL will provide significant pectinolytic activity as well as cellulase and hemicellulase side activity.

• ClariSEB provides even stronger pectinase activity with very little cellulase and hemicellulase activity.

4) The mash is then sent to hydraulic presses that squeeze the mash to extract the juice. A single press usually yields only about 60 - 70% of the JUICe from fresh apples. Stored apples produce less juice and their untreated pomace tends to stick to the press. This is caused by protopectin hydrolysis that occurs during ripening, which separates cells and softens the fruit.

Water is added to the pulp residue and It IS completely expressed, usually with a horizontal press. The increase in juice voltme isn't great, but the increase in sugar is significant. Normal juice is about 12 Brix. The second press sugar (apple

sugar) can raise the juice to 12.3 to 12.5 Brix.

5) The apple juice is then pumped to holding tanks where it is filtered to remove sediment. If Pectinase was not added during mash, it can be added to the holding tanks. The use of a product like LiquiSEB or ClariSEB will reduce viscosity,

prevent or reduce clogging of the filters and increase filtration rate. If LiquiSEB was used during the mash, ClariSEB could be used at this step to further reduce viscosity and clarify the product.

LiquiSEB can also be used when the tanks are cleaned to help unclog filters.

6) The filtered juice is then pumped into clarification tanks. Hazy apple juice is desirable to some, especially in Japan. Others feel cloudy apple juice is more natural and is popular in health food stores and natural food markets. The cloudiness is due to pectin and/or starch. Unripe or early season apples have rather high levels of starch compared to mid and late season harvest apples.

Again, LiquiSEB or ClariSEB will reduce the cloudiness from pectin. SEBamyl-L is an endo-amylase that will break down the starch into dextrins and maltose. SEBamyl-GL is an exo-amylase that should eliminate the haze and produce additional glucose.

7) Once the juice is clarified, it is again filtered, though most companies now use Ultrafiltration*. The pore size in a microfilter is 0.1 and 10 µ** in diameter. The pore size for ultrafilter is between 0.001 and 0.1 µ. As a result, molecules as large as 10,000 daltons can clog these filters, slowing filtration rate and requiring expensive cleaning. If the juice was previpusly treated with pectinase and amylase enzymes, filtration will proceed properly and clogging should, not occur.

8) The enzyme treated and twice-filtered apple juice goes to one of the two places:

(a) Directly to the bottling line - where it is pasteurized and filled into bottles and cooled.

(a) Some apple juice is sent to concentrators where much of the water is removed to make a thick concentrate, which is typically 70 Brix.

This is then stored cold in sanitized stainless steel tanks to wait to be bottled at any time.

Labeling

In most countries, enzymes used in food and juice processing are considered processing aids, not food additives. As a result, they are usually not required on the label. However, you must check the labeling requirements of your own country.

As this brief description illustrates, juice processing is complex. If you have questions about juice processing in your plant, Please contact info@mdi.vn. We will be happy to help you select the correct mix of enzymes for your production process.